CASE

MANUFACTURING CAPACITY

EXPANSION

CREATING MORE SPACE

COMMITMENT & EFFICIENCY BUILDING SOLUTIONS

Backstory

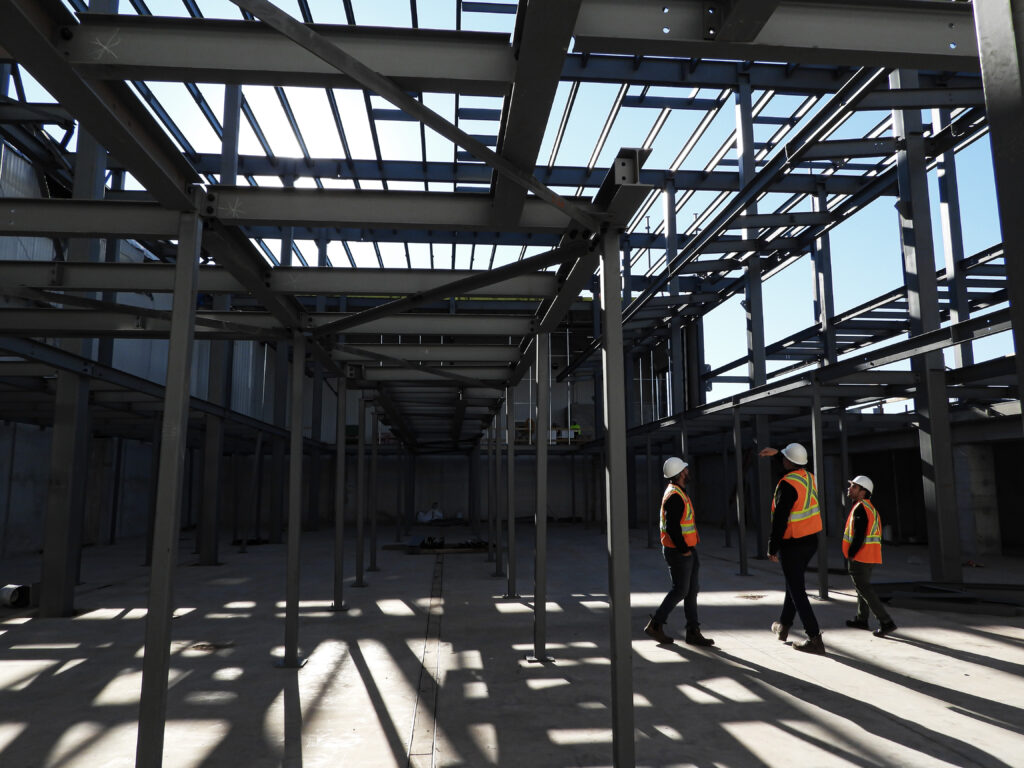

A multinational aerospace company in Oakville needed more space to meet the spatial requirements for new processes, equipment and infrastructure.

MeadowBrook Construction was contracted to manage the construction of the new structure within part of the existing facility.

The project was completed on time and on budget, accomplishing the client’s expanded capacity requirements as planned.

Project Requirements

- Add 120 square meters of floor space, including multiple mezzanines

- Create a 12-foot pit, with a 6-foot roof raise, to raise the overall structure to a height of 42 feet from 24 feet, and

- Address impacts on landscape, stormwater management, fire exiting, ventilation, structure, power capacity, sprinkler systems and domestic water systems.

CLIENT NAME

Confidential

SECTOR

Aerospace

LOCATION

Oakville

COMPLETION

2023

CONTRACT TYPE

Construction

PROJECT SIZE

$12.5 Million

CLIENT NAME

LOCATION

SECTOR

MARKET

COMPLETION

CONTACT TYPE

PROJECT SIZE

Confidential

Oakville

Aerospace

Aircrafts

2023

Construction

$12.5 Million

CLIENT NAME

Confidential

LOCATION

Oakville

SECTOR

Aerospace

MARKET

Aircrafts

COMPLETION

2023

CONTACT TYPE

Construction

PROJECT SIZE

$12.5 Million

THE CHALLENGE

Improve their customer experience

Local & regional environmental stewardship took time and care upfront

In a project such as this, there are many challenges. One of the most challenging was the physical expansion toward neighbouring properties. We needed to prove to the city and the region that the expansion would not negatively impact the stormwater management from the property to the creek nearby. Discussions were had with the region of Halton and Oakville’s site plan examiners. We also consulted with Oakville’s plumbing inspectors. We were able to present a design (with backup for validation) that allayed any concerns they may have had.

Shale added extra considerations

The building itself is on shale. This required heavy excavating equipment and chipping machines which required big footings. This added an extra level of intricacy to the logistics of the build.

HVAC requirement for high air change rate

As a manufacturing space, the HVAC requirements were very high – at a high air change rate to allow for safe operation of the dipping and coating that's going to happen in that area.

THE CHALLENGE

Local & regional environmental stewardship took time and care upfront

In a project such as this, there are many challenges. One of the most challenging was the physical expansion toward neighbouring properties. We needed to prove to the city and the region that the expansion would not negatively impact the stormwater management from the property to the creek nearby. Discussions were had with the region of Halton and Oakville’s site plan examiners. We also consulted with Oakville’s plumbing inspectors. We were able to present a design (with backup for validation) that allayed any concerns they may have had.

Shale added extra considerations

The building itself is on shale. This required heavy excavating equipment and chipping machines which required big footings. This added an extra level of intricacy to the logistics of the build.

As a manufacturing space, the HVAC requirements were very high – at a high air change rate to allow for safe operation of the dipping and coating that's going to happen in that area.

THE SOLUTIONS

HVAC requirement for high air change rate

The key to maintaining a fast pace when timeframes are tight, truly lies in all parties working together – Glendale Group’s design teams, MeadowBrooks’ construction teams, and third-party consultants – to not only keep everyone informed but also to collaborate on-the-spot, in real-time, as challenges come up. This was crucial to our success in delivering the completed building less than a year after starting the demolition.

THE SOLUTIONS

Improve their customer experience

Multiple teams working as one team helps maintain the pace

The key to maintaining a fast pace when timeframes are tight, truly lies in all parties working together – Glendale Group’s design teams, MeadowBrooks’ construction teams, and third-party consultants – to not only keep everyone informed but also to collaborate on-the-spot, in real-time, as challenges come up. This was crucial to our success in delivering the completed building less than a year after starting the demolition.

THE PROCESS

Collaborative process with 100% satisfaction of the client.

The Glendale Group and MeadowBrook Construction have a close relationship that benefits every project we work on together. We take pride in recognizing clear examples of our relationship in action. On this project, the initial design did not have a weeping element. Once onsite, construction team members discovered there was a case to be made for weeping. Working closely with the designers, they were able to start preparing the site for weeping, while the designs were being updated. Being able to work so well together – dynamically, in real-time – meant that the work was done only once and the project moved forward without the weeping system causing a delay. This made us and our client very happy.

The Glendale Group and MeadowBrook Construction have a close relationship that benefits every project we work on together. We take pride in recognizing clear examples of our relationship in action. On this project, the initial design did not have a weeping element. Once onsite, construction team members discovered there was a case to be made for weeping. Working closely with the designers, they were able to start preparing the site for weeping, while the designs were being updated. Being able to work so well together – dynamically, in real-time – meant that the work was done only once and the project moved forward without the weeping system causing a delay. This made us and our client very happy.

Are you looking for a similar project?

We partner with our clients to overcome their facility challenges. From construction to building maintenance, we offer a multi-trade end-to-end solution capable of build your vision.

NEWSLETTER

Stay in touch

Get bi-weekly news and educational content in your inbox by subscribing to our newsletter!

LOOKING FOR AN OPPORTUNITY

Being part of a solid team, with strong values and a clear vision for the future, you’ll grow both personally and professionally.